What is ultrasonic welding machine

Ultrasound we know that when an object vibrates, it makes a sound. Scientists call the number of vibrations per second the frequency of sound, in Hertz. The frequency of sound waves that we can hear in human ears is 20-20000 Hz. When the frequency of sound waves is greater than 20000 Hz or less than 20 Hz, we can't hear them. Therefore, we call the sound wave with frequency higher than 20000 Hz as "ultrasonic wave". The frequency of ultrasound usually used in medical diagnosis is 1-5 MHz. Ultrasonic wave has the characteristics of good directivity, strong penetration, easy to obtain concentrated sound energy, and long distance in water. It can be used for ranging, speed measuring, cleaning, welding, gravel, etc. It has many applications in medicine, military, industry and agriculture.

The theoretical study shows that the energy of vibration of an object is directly proportional to the vibration frequency under the condition of the same amplitude. When ultrasonic wave propagates in medium, the vibration frequency of medium particle is very high. In the dry winter of northern China, if the ultrasonic wave is put into the water tank, the water in the tank will be broken into many small droplets by violent vibration, and then the droplets will be blown into the room by a small fan, which can increase the indoor air humidity. This is the principle of ultrasonic humidifier, laryngitis, tracheitis and other diseases, call Jinnian Jinbai, it is difficult to blood flow to the location of the disease. The principle of humidifier is used to atomize the medicine liquid and let the patient inhale it, which can improve the curative effect. The huge energy of ultrasound can also make the stones in human body broken by violent forced vibration, so as to slow down the pain and achieve the purpose of cure.

In the process of welding, the workpiece and solder melt to form a melting area, and the connection between materials is formed after the molten pool is cooled and solidified. In this process, pressure is usually applied. There are many kinds of welding energy sources, including gas flame, arc, laser, electron beam, friction and ultrasonic. Before the end of the 19th century, the only welding process was forge welding of metal, which was used by blacksmiths for hundreds of years. The earliest modern welding technology appeared at the end of the 19th century, first arc welding and oxy fuel gas welding, and then resistance welding. In the early 20th century, with the first and second world wars, there was a great demand for cheap and reliable connection methods of military equipment, which promoted the development of welding technology. With the wide application of welding robot in industrial application, researchers are still in-depth study on the nature of welding and continue to develop new welding methods to further improve the welding quality.

In the 21st century, the use of ultrasound is more and more widely used. At present, it is widely used in medical, military, industrial, agricultural, chemical and other fields. Today, we mainly talk about the application of ultrasonic wave in industrial field -- ultrasonic welding!

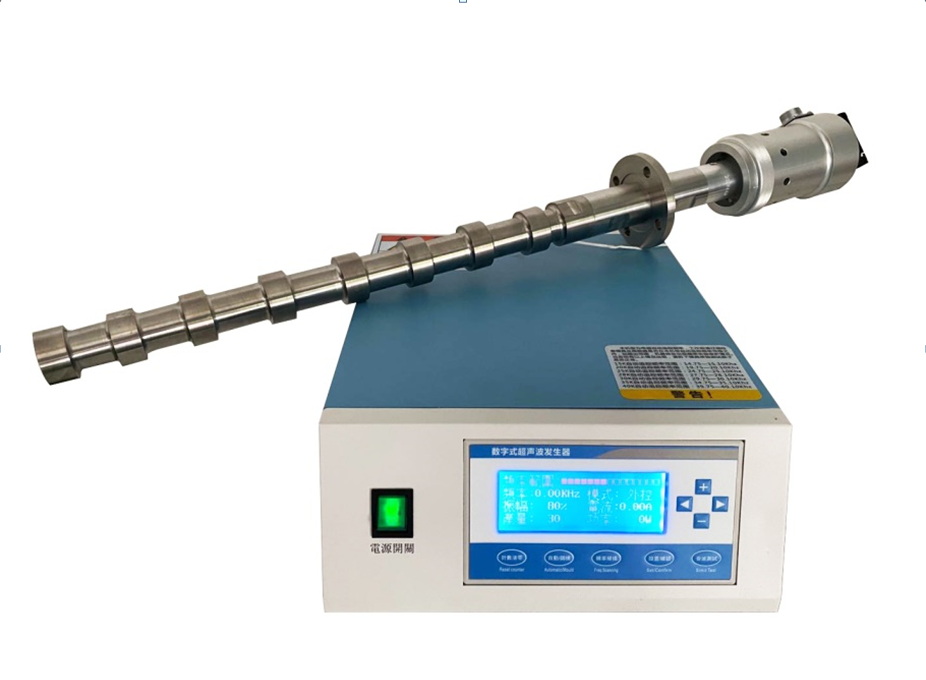

Ultrasonic welding machine is to convert 50 / 60 Hz current into 15, 20, 30 or 40 kHz power by ultrasonic generator. The converted high-frequency electricity can be converted into mechanical motion of the same frequency again through the transducer, and then the mechanical movement is transmitted to the welding head through a set of amplitude transformer device which can change the amplitude. The vibration energy received by the welding head is transferred to the joint of the workpiece to be welded. In this area, the vibration energy is converted into heat energy by friction, and the plastic is melted. Ultrasound can be used not only to weld hard thermoplastic plastics, but also to process fabrics and films.

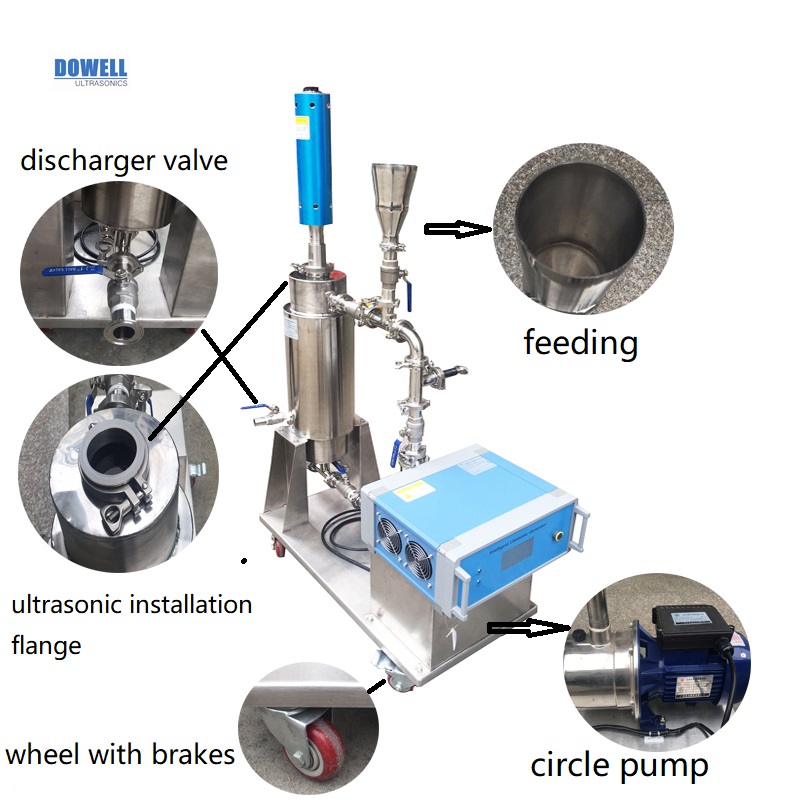

The main components of a set of ultrasonic welding machine include ultrasonic generator, transducer / Horn / welding head, mould and frame.

Linear vibration friction welding uses the friction heat generated by the contact surface of two workpieces to melt the plastic. Heat energy comes from a certain pressure, a workpiece in another surface with a certain displacement or amplitude of reciprocating movement. Once the expected welding degree is reached, the vibration will stop, and at the same time, there will still be a certain pressure applied to the two workpieces to cool and solidify the just welded parts, thus forming a close combination.

Rail vibration friction welding is a kind of welding method using friction heat energy. In the rail vibration friction welding, the upper part of the workpiece at a fixed speed for rail motion - circular motion in all directions. The movement can generate heat energy to make the welding part of two plastic parts reach the melting point. Once the plastic begins to melt, the movement stops and the welded parts of the two pieces solidify and are firmly connected. Small clamping force will lead to a small degree of deformation of the workpiece. Workpieces within 10 inches in diameter can be welded with rail vibration friction.

Advantages of ultrasonic plastic welding machine:

1. Fast welding speed, high welding strength and good sealing performance; it can replace the traditional welding bonding process.

2. Low cost, clean and pollution-free, and will not damage the workpiece; welding process is stable.

3. All welding parameters can be tracked and monitored through the software system. Once the fault is found, it is easy to remove and maintain.

Advantages of ultrasonic metal welding machine:

1. The welding material is not molten and not fragile metal properties.

2. After welding, the conductivity is good and the resistance coefficient is very low or near zero.

3. Low requirement for welding metal surface, oxidation or electroplating can be welded.

4. The welding time is short, without any flux, gas and solder.

5. Welding without spark, environmental protection and safety.

Contactus

David wang

Hangzhou Dowell Ultrasonic Tech Co.,Ltd

Factory Add:No.8 Shengda RD,Fuyang District,Hangzhou,China

Office Add:No.107,Fengshou RD,Fuyang district,Hangzhou.China

TEL:86-571-87191379; +86-15088693503

wechat and whasapp:15088693503

FAX:86-571-87191379

Email:davidwang@dowellsonic.com

zip code:311400