- Maintenance of mask ultrasonic spot welding machine[ 2020-09-18 ]

- 1. Keep the spot welding machine and its worktable clean 2. Keep the spot welding head clean. Do not mix other hard objects, especially iron nails, into the mesh, so as not to damage the machine or affect the welding effect. 3. The long-term welding of aluminum will lead to the adsorption of upper and lower welding joints. According to the weldi

- Causes and solutions of unsound welding of ultrasonic mask spot welding machine[ 2020-09-18 ]

- 1. The machine uses a voltage of 220 v. before power on, the collective grounding should be made, and the grounding resistance should not be greater than 4 ohm. 2. When the voltage fluctuation is large, the machine should be installed with AC transformer, which can reduce the loss of the machine and ensure the safe and stable operation of the mac

- Application of ultrasonic spot welding machine in automobile manufacturing industry[ 2020-09-18 ]

- Ultrasonic spot welding machine is also known as handheld ultrasonic spot welding machine. Pistol type ultrasonic welding is usually used for riveting plastic products. It is widely used in automobile manufacturing industry, especially in the manufacturing and processing of internal and external plastic parts. Hand held ultrasonic spot welding m

- What is ultrasonic welding machine[ 2020-09-18 ]

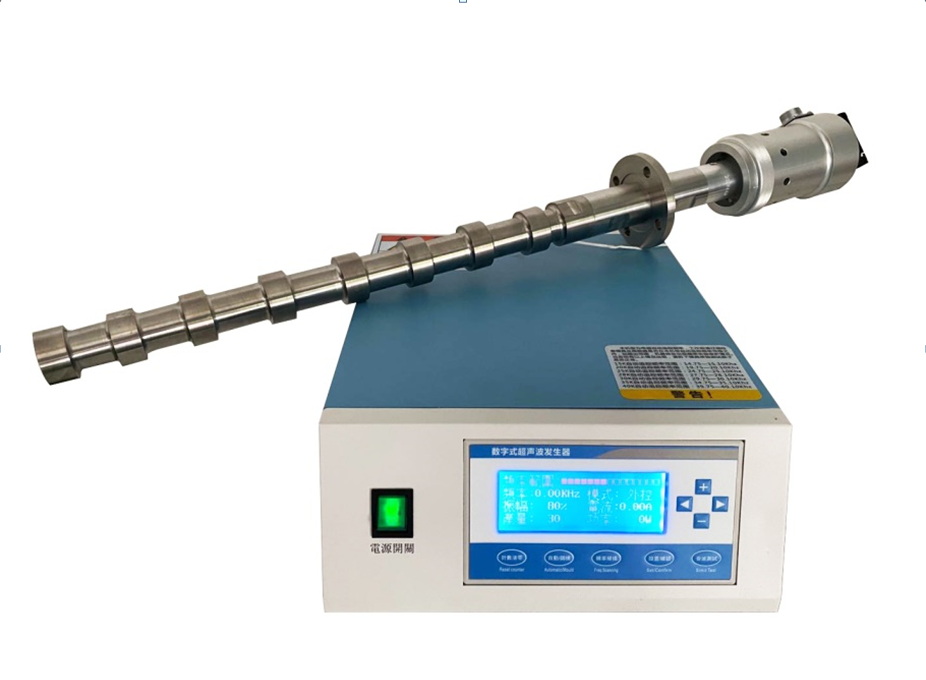

- Ultrasound we know that when an object vibrates, it makes a sound. Scientists call the number of vibrations per second the frequency of sound, in Hertz. The frequency of sound waves that we can hear in human ears is 20-20000 Hz. When the frequency of sound waves is greater than 20000 Hz or less than 20 Hz, we can't hear them. Therefore, we cal

- Advantages of ultrasonic welding machine[ 2020-09-18 ]

- There are many types of ultrasonic welding machine, according to the level of automation can be divided into automatic welding machine, semi-automatic ultrasonic welding machine, manual welding machine. Ultrasonic welding machine, then, for modern enterprises, the higher the level of automation, the more conducive to the production line, so the us

- Characteristics and application of ultrasonic mask ear band spot welder[ 2020-09-16 ]

- The ultrasonic generator converts 50 / 60 Hz current to 20 kHz. The sensor converts it into mechanical motion of the same frequency again and transmits it to the welded joint through the amplitude modulator. The vibration energy received by the welded joint is transferred to the non-woven fabric mask joint to be welded, and the vibration energy is

- Tin plating and welding of ultrasonic soldering iron equipment[ 2020-09-14 ]

- Traditional tin plating equipment usually uses corrosive flux to remove oxide layer or impurity on the surface more or less. In addition, it is impossible to weld materials such as glass, ceramic and aluminum with traditional tin plating equipment. The new technology of ultrasonic driven welding joint does not need to add corrosive acid / flux. &

Contactus

Hotline:

+86-15088693503

WhatsApp:+86-15088693503

David wang

Hangzhou Dowell Ultrasonic Tech Co.,Ltd

Factory Add:No.8 Shengda RD,Fuyang District,Hangzhou,China

Office Add:No.107,Fengshou RD,Fuyang district,Hangzhou.China

TEL:86-571-87191379; +86-15088693503

wechat and whasapp:15088693503

FAX:86-571-87191379

Email:davidwang@dowellsonic.com

zip code:311400